All of the Swatches

This past week has been the week of swatching. I want to start a new rayon shadow weave shawl. I love the light-colored neutral shawl I made at the beginning of the year, and want something similar with a bit more depth of color. I have a shelf of 8/2 Rayon in my stash, and

New Loom

Well, new to me at least. I have been looking for a Baby Mac for ages, and I finally have one. 🙂 It’s first warp is, of course, shadow weave. This will be a rayon shawl: CP-6485 has a new and happy home. 🙂 Just as I wold expect from Macomber, this lovely machine weaves

New Studio 2025

The cats looking out to the sunroom/ future studio in our new home. We spent last night here for the first time. Our stuff should get here in a couple days and I’m looking forward to making awesome things in this room sooooon. very soon. 🙂

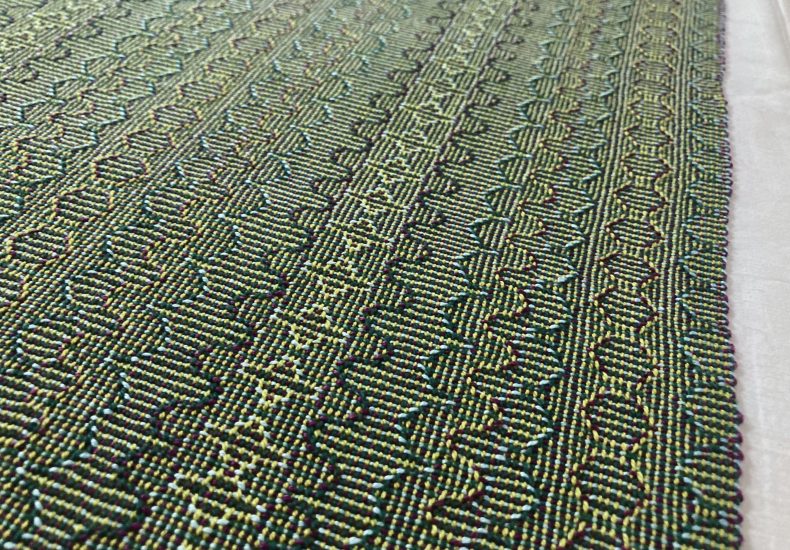

The Beauty of Shadow Weave

I love this fabric so much! The way the warp and weft optically blend into so many different colors in this four-color shadow weave pattern is just so visually pleasing. It’s a mix of a muted dark green and a vivid yellow-green in the warp, crossed with a muted maroon, and a bright icy blue

Pain

I just realized I can’t remember what it was like to be in constant pain. It’s wonderful and freeing and also I want to have a record of it, if only to better appreciate its absence. In the years of my pain I described it as living inside a cage that was slowly shrinking. At

Cat tax

Is there anyone in/near Raleigh, NC with a baby mac I could come visit? I am seriously considering pulling the trigger on ordering one, but would really like to sit at one and make sure the ergonomics will work for me. photo of a recent project from my big mac that has been adopted by

Interlude

Welp. It’s been a minute. I’ve been dealing with chronic nerve pain since a car accident in 2017. It had been getting worse and worse in spite of medical care and physical therapy. It crippled me in late January following a cross-country plane flight. After trying every other thing possible, I finally decided to have

2024: the Year of Shadow Weave

The second shadow weave warp has been wound on: and woven off: I am still absolutely in love with this structure. I have so many plans for this year.

Shadow weave is calling me

I checked Marian Stubenitsky’s book Max8 out from my Guild’s library in December, and was captivated by the Shadow Weave patterns she has on p. 26-28. I copied her draft into iWeaveIt, noodled around with it a bit, warped up my Big Mac, sleyed a twill sett, and ended up with this: I realized I

New Studio

The studio is coming together. I moved to Raleigh, NC in August, and finally my studio is well set up and I’m weaving. This is a wildly distorted panorama picture, but it shows the view from my sewing table (which is behind me so not shown) towards the windows. It’s a daylight basement in a